Quality

Quality Assurance is at the heart of everything we do here at Golden Metal. Quality of our products, quality of our service and quality in our people. It will come as no surprise to our clients that we take our quality assurance processes very seriously indeed.

The company’s commitment to quality and health and safety is introduced to all employees from day one, as it is emphasised during their training and induction period. Staff members are encouraged to be proactive with bringing suggestions to the attention of the management team and regular staff meetings are held to foster discussion.

FAQs

We interviewed Beryl Richmond, Golden Metal Quality Assurance Manager, to ask how Golden Metal ensures best practice from our suppliers to our global sites, and why quality assurance is so important:How would you define quality assurance?

Quality Assurance is about trying to give the best possible service to our customers while ensuring our staff are safe and our processes are consistent. You have to be continually asking yourself ‘what is good service’ and ‘what is best practice’. Only by working on the answers to these questions every day will you achieve true quality and reliability.

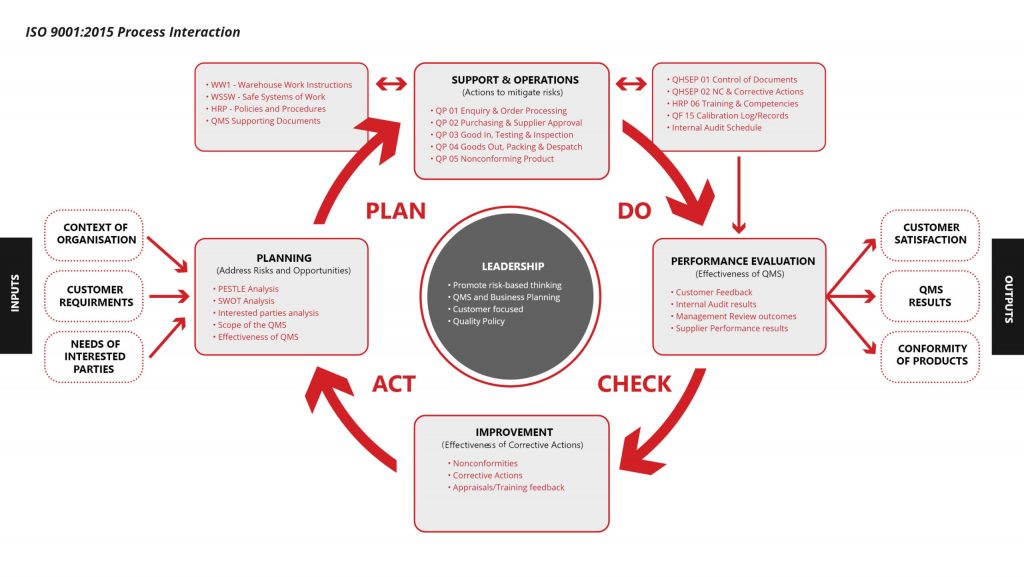

How is the Quality Assurance process managed at Golden Metal?

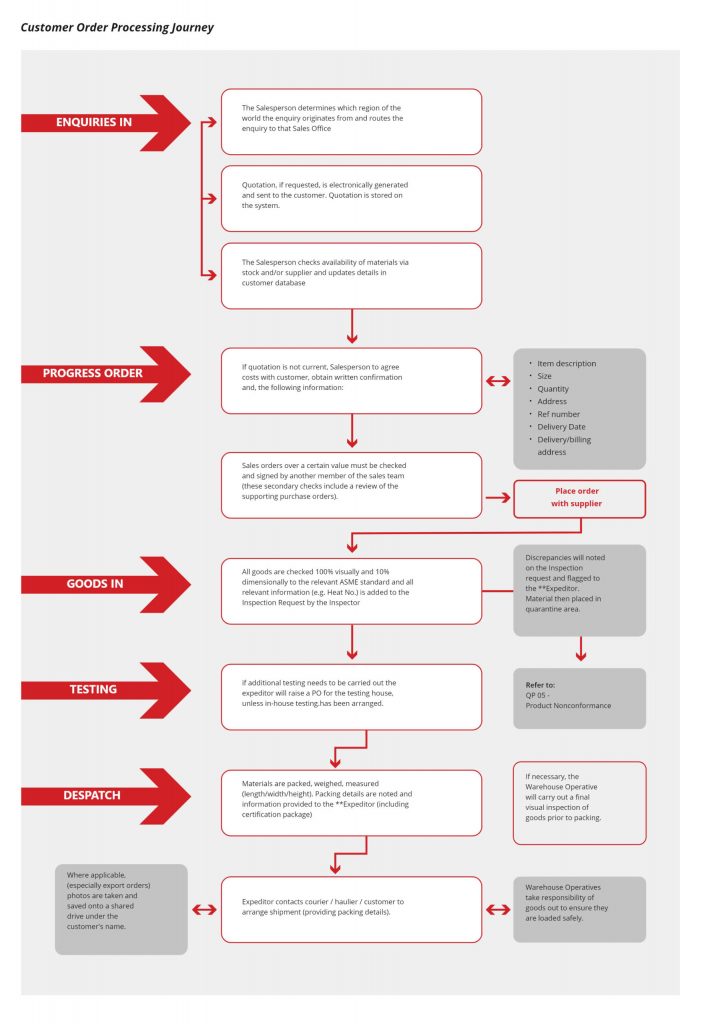

We have a robust set of procedures and policies in place to ensure that mistakes aren’t made, and everything is done with the customer in mind. On a basic level we try to make sure that the product is right, it’s in good condition, is properly inspected, is packaged well and is delivered on time.

One of the most important things that we do is to measure ourselves through customer feedback. We try to gather feedback on every job that we complete so that we can keep an accurate measure of our customer satisfaction levels. If any challenges have arisen, then we ensure that we work through them systematically and we are always looking to improve.

Quality assurance is not something that you can ever ‘stop doing’ as it has to be a flexible system that you can update, improve and develop on a regular basis.

How do you ensure quality across all the Golden Metal global sites?

Having such a vast global network of offices is certainly a challenge. Every office has its own priorities and concerns, so we have to ensure that all the policies and procedures are relevant and appropriate. At the end of the day though, we all have a common goal that is customer satisfaction.

Each office has a dedicated quality assurance person and all the global senior management team take quality assurance very seriously and therefore ensure that their teams feel the same way.

How do you maintain the quality standards at Golden Metal?

These days, our clients are requesting an increasing amount of detail in regard to our policies and procedures which means it is even more important to ensure that our systems are up to scratch. They don’t just want to see our certificates but they, quite rightly, want to know in-depth information about our policies.

We are audited three times a year by the British Standards Institution (BSI) to ensure our compliance and our customers themselves can audit us at any time they wish. We often get audited by clients prior to being placed on their approved supplier lists. This is obviously extremely important to develop trust and confidence in our service.

We habitually conduct risk assessments, internal audits and train all staff on a regular basis – all of which are important assignments if we are to improve and grow.

How do you ensure quality throughout the Golden Metal supply chain?

We ask all our suppliers to hold a ISO9001 certification and we ensure that they have robust systems in place to protect themselves and us from any potential challenges that may arise.

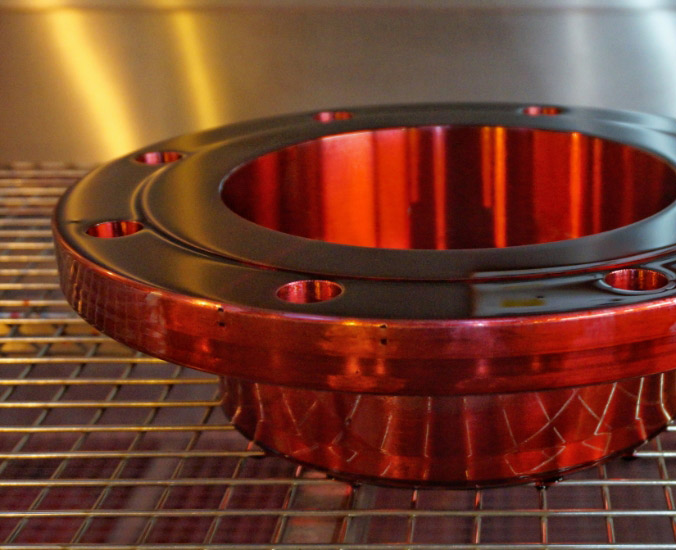

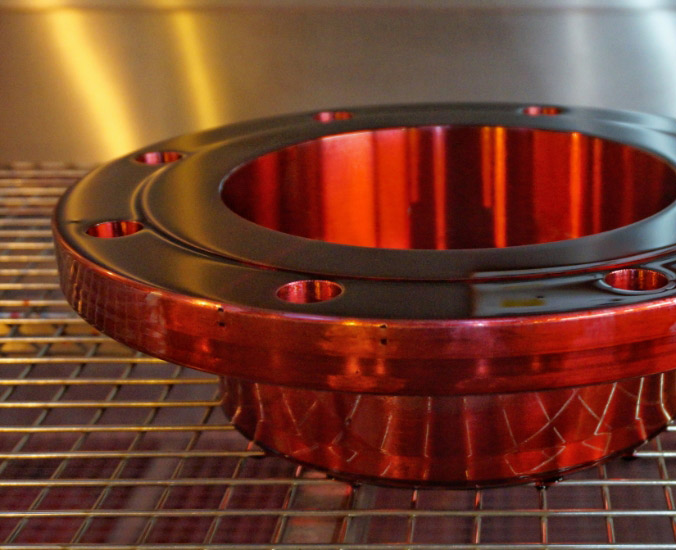

All our highly specialised materials carry their own documentation and have to undergo certain inspections and even tests to ensure compliance.

Order Processing Journey